Steam locomotive

A steam locomotive is a locomotive powered by steam. The term usually refers to its use on railways, but can also refer to a "road locomotive" such as a traction engine or steamroller.

Steam locomotives were the dominant form of rail traction from the mid 19th century until the mid 20th century, after which they were superseded by diesel and electric locomotives.

Contents

Origins

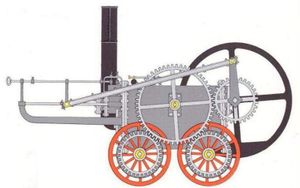

The earliest railways employed horses to draw carts over the track. As steam engines were developed in the 1700s, various attempts were made to apply these to railroad use.[1] The first attempts were made in Great Britain; the earliest steam locomotive was built in 1804 by Richard Trevithick and Andrew Vivian. It ran with mixed success on the narrow gauge Penydarren tramway in Wales.[1] These early efforts culminated in 1829 with Stephenson's Rocket, which was the first viable mainline locomotive.[2]

Inspired by British success, the United States started developing steam locomotives in 1829 with the Baltimore and Ohio Railroad's Tom Thumb. This was the first locomotive to run in America although it was intended as a demonstration of the potential of steam traction, rather than as a revenue-earning locomotive. The first successful steam railway in the US was the South Carolina Railroad whose inaugural train ran in December 1830 hauled by the Best Friend of Charleston. Many of the earliest locomotives for American railroads were imported from England, including the Stourbridge Lion and the John Bull, but a homegrown locomotive manufacturing industry was quickly established, with locomotives like the DeWitt Clinton being built in the 1830s.[3]

See also: Category:Early steam locomotives

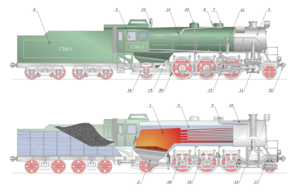

Basic form

The typical steam locomotive employs a horizontal fire-tube boiler with the firebox at the rear. The firebox projects into the cab, which shields the locomotive operators from the weather. At the front of the boiler is the smokebox, with chimney (US: "smoke stack") protruding from the top. Steam is collected from the top of the boiler, either in a perforated tube fitted above the water level or from a dome, which reduces the risk of water entering the cylinders. The steam passes through a throttle (known as the "regulator valve") and then to the cylinders of a reciprocating engine. The pistons of this engine drive the driving wheels directly through a connecting rod (US: "main rod") and a crankpin on the main driver. The valves of the engine are controlled through a set of rods and linkages called the valve gear; this gear is adjustable to control the direction and cut-off of the valve gear. The cut-off point determines the proportion of the stroke during which steam is admitted into the cylinder; for example a 50% cut-off admits steam for half the stroke of the piston. The remainder of the stroke is driven by the expansive force of the steam. Careful use of cut-off leads to economical use of steam and hence fuel and water. The reversing lever (US: "Johnson bar", or "screw-reverser" if so equipped) which controls the cut-off is therefore roughly analogous to the gearshift of an automobile. Exhaust steam is directed through the chimney via a nozzle called a blastpipe, thus roughly regulating the draft of the engine according to the steam consumed. The blast of exhaust produces the familiar "chugging" sound of the steam locomotive. The pistons are double acting; a two-cylinder locomotive (the typical form) has one cylinder on either side of the locomotive, set 90 degrees out of phase with each other, which gives four power strokes per revolution of the wheels. The driving wheels are connected on each side by coupling rods (US: "connecting rods") to transmit power from the main driver to the other wheels.

The boiler rests on a frame to which the cylinders are mounted and which in turn rest on the axles. The driving axles are mounted in bearings which can move up and down in the frame. They are also connected to the frame via leaf springs or, less commonly, volute springs and linkages which allow axles some degree of independent movement in order to handle bumps in the track. Many locomotives have a leading bogies (US: "trucks") to guide them into curves and/or a trailing bogie to support the firebox weight.

Most locomotives are permanently coupled to a tender that carries the water and fuel for the locomotive. Some locomotives carry the fuel and water directly on the engine itself; these are called "tank engines" after the prominent tanks atop or alongside the boiler. From the beginning the predominant fuel was coal in the UK, though wood-burning engines were used in rural and logging enterprises, and wood enjoyed widespread use in the U.S. well into the 19th century. Bagasse was burned in sugar cane farming operations. When petroleum came into wide use, oil-burning locomotives were used in some areas; the Southern Pacific went directly from wood to oil[citation needed]. In principle, anything that can be obtained in bulk and burned readily in the firebox can be used for fuel.

A steam locomotive is operated by a crew of at least two people. One, the driver or engineer, is responsible for controlling the locomotive (and thus the train as a whole); the other, the boilerman or fireman, is responsible for the fire, pressure, and water. [4]

See also Category:locomotive parts

Fittings and appliances

Almost all locomotives are fitted with a variety of appliances. Some of these relate directly to the operation of the steam engine; while others are for signalling, train control, or other purposes. In the United States the Federal Railroad Administration mandated the use of some appliances over the years in response to safety issues. The most typical appliances are as follows:

Steam pumps and injectors

A device is required to force water into the boiler. Early engines used pumps driven by the motion of the pistons; later on steam injectors took their place, and some engines use turbopumps. Standard practice is to have two independent systems for feeding water to the boiler. Vertical glass tubes, known as water gauges or water glasses, show the level of water.

Boiler lagging

It was recognised from the outset that large amount of heat would be wasted from a boiler that was not insulated. Early locomotives used shaped battens of wood fitted lengthways along the barrel and held in place by metal bands. Later methods included: applying a thick paste containing a porous mineral such as kieselgur, fixing "mattresses" of stitched asbestos cloth stuffed with asbestos fibre around (but on separators so as not quite to touch) the boiler, or attaching shaped blocks of insulating compound. The most common material in use today is glass wool, but wrappings of aluminium foil are also found. The installation is finished off by a closely fitted sheet-metal casing.[5]

Pressure gauge

On the earliest locomotives there was no provision to show the pressure of steam in the boiler, but it was possible to estimate this from the state of the safety valve. However, the promoters of the Rainhill trials urged that each contender should have a proper mechanism for this and Stephenson devised a nine-foot vertical glass tube of mercury, mounted alongside the chimney, for the Rocket. The Bourdon tube gauge, in which the pressure straightens an oval-section, coiled tube of brass or bronze connected to a pointer, was not introduced until the 1850s. This is the device in use today.[6] On some locomotives an additional pressure gauge is fitted in the steam chest. This helps the driver avoid wheel-slip at startup by warning if the selected regulator opening is too great.

Superheating

In the 1800s most engines used saturated steam. Post-1900 superheated steam appeared in the U.S.A. Prior to super heating locomotive development had almost reached its practical capacity with saturated steam. Swengel said that 'no single development ever equalled the superheater as a means of removing limitations from steam locomotive design'.(p.122.)

The normal method for superheating is to route the steam from the dome to a header in the smokebox. The steam is then directed through a set of small "U" shaped tubes in enlarged boiler tubes, and then into a second header and on through the cylinders. Superheating produces an increase in efficiency of 10-15% for an increase in temperature of 100 to 150 F° (55 to 85 C°) in a locomotive already designed for economy, but in many types even larger increases were found.

One pound of saturated steam at 200 p.s.i. occupies 2.134 cubic feet of space and when admitted to the cylinders the water (condensation)content is about 7%. At higher boiler pressure the water content in the cylinder increases. Prior to superheating, the boiler limit for any given locomotive was 200 p.s.i. as a locomotive could not as a rule, handle more than 7% water in its cylinders. Superheating, in short, dries out the steam, increases its volume and this gain increases the amount of work delivered from the same one pound of water. Superheating increased the tractive effort of a modified locomotive over its prior saturated condition. A bad practice which followed the initial introduction of superheating involved dropping the boiler pressure to achieve the same tractive effort, increasing the cylinder size to obtain increased work and removing many small tubes and replacing them with larger diameter flues to hold the super heaters. These modifications actually lessened tha amount of evaporate surfaces than the old saturated boiler and limited the capacity of the locomotive. (Swengel, p.122.) Had the boiler pressure remained the same following super heating the overall effectiveness of the locomotive would have increased. By the mid-1920s, designers understood that superheating, large furnaces and higher boiler capacity were the key to successful locomotives.(Swengel, p.204.)

For this reason it was common to find that the best improvements were not until locomotives were some way into their overhaul cycle and leaks had started to develop.[7] The practice became standard in all high-powered locomotives of the 20th century.

Stokers

A factor that limits the power produced is the rate at which fuel can be added to the fire. In the early 20th century some locomotives became so large that the fireman could not shovel coal in fast enough[citation needed]. In the United States various steam-powered mechanical stokers were introduced and became standard equipment by the end of the steam era.

Feedwater heaters

Introducing cold water into a boiler reduces power, and from the 1920s a variety of heaters were introduced to extract waste heat from the exhaust and raise the temperature of the feed water.

The use of live steam and exhaust steam injectors also assists in the pre-heating of boiler feed water, though there is no efficiency advantage to live steam injectors. Such pre-heating also reduces the thermal shock that a boiler might experience when cold water is introduced directly.

Condensers and water re-supply

Steam locomotives consume vast quantities of water, and supplying this was a constant logistical problem[citation needed]. In some desert areas condensing engines were used. These had huge radiators in the tenders through which the exhaust steam was passed to condense it back to water and replenish the tender. These engines particularly saw use in the Karoo desert. Where condensers were used, care had to be taken to ensure cylinder lubricating oil was removed from the water fed back into the boiler to avoid a phenomenon known as priming, in which foam in the boiler could cause water to be carried into the cylinders, causing damage because of its incompressibility.

At the other extreme, tenders on some British and American locomotives were equipped with scoops to allow them to collect water from "water troughs" (US: "track pans") while in motion, thus avoiding stops for water.

Braking

Locomotives have their own braking system, independent from the rest of the train. Locomotive brakes employ large shoes which press against the driving wheel treads. With the advent of air brakes, a separate system also allowed the driver to control the brakes on all cars. These systems require steam-powered pumps, which are mounted on the side of the boiler or on the smokebox front.

An alternative to the air brake is the vacuum brake. Where vacuum brakes are used, a steam-operated ejector is mounted on the engine instead of the air pump. A secondary ejector or crosshead vacuum pump is used to maintain the vacuum in the system.

Lubrication

The pistons and valves on the earliest locomotives were lubricated by the simple expedient of one of the enginemen dropping a lump of tallow down the blast pipe.[8] As speeds and distances between stops increased, mechanisms were devised to inject thick mineral oil into the steam supply. The first is a displacement lubricator, mounted in the cab, which uses a controlled bleed of steam condensing into a sealed container of oil. The water from the condensed steam displaces the oil into pipes. The apparatus is usually fitted with sight-glasses to confirm the rate of supply. A later method uses a mechanical pump worked from one of the crossheads. In both cases the supply of oil is proportional to the speed of the locomotive.

The provision for lubricating the frame components (axle bearings, horn blocks and bogie pivots) usually depends on capillary action: trimmings of worsted yarn are trailed from oil reservoirs into pipes leading to the respective component.[9] The rate of supply is controlled by the size of the bundle of yarn and not the speed of the locomotive, so it is necessary to remove the trimmings (which are mounted on wire for this purpose) when stationary, but at regular stops (such as a terminating station platform) oil finding its way onto the track can be a problem.

Crank pin and crosshead bearings carry small cup-shaped reservoirs for oil. These have feed pipes to the bearing surface that start above the normal fill level, or are kept closed by a loose-fitting pin, so that only when the locomotive is in motion does oil enter. In United Kingdom practice the cups are closed with simple corks, but these have a piece of porous cane pushed through them to admit air. It is customary for a small capsule of pungent oil (aniseed or garlic) to be incorporated in the bearing metal to warn if the lubrication fails and excess heating or wear is taking place.

Pilots and buffers

In British practice, the locomotive is usually provided with buffers at each end to take any compressive loads (buff forces). The tensional load of drawing the train (draft force) is carried by the coupling system. Together these control slack between the locomotive and train, absorb minor impacts, and provide a bearing point for pushing movements. In American practice all of the forces between the locomotive and cars are handled through the coupler and its associated draft gear, which allows some limited slack movement. Small recesses called "poling pockets" were also provided at the front and rear corners of the locomotive to allow cars to be pushed on an adjacent track using a pole braced between the locomotive and the cars.

In the United States, South Africa and Australia the focus at the front of the locomotive turned to dealing with obstructions on the track, and the pilot was developed. This is a plow-shaped apparatus that was originally quite large, but which even in vestigial form was retained on mainline steam locomotives to the very end. It is popularly known by the literative misnomer "cowcatcher". Switching engines usually replace the pilot with small steps. (See Gerald A Dee in books below)

Headlights

When night operations began, railway companies in some countries equipped their locomotives with lights to allow the driver to see what lay ahead of the train or to enable others to see the locomotive. Originally headlights were oil or acetylene lamps, but when electric lights became available they quickly replaced the older types.

In Britain, only low intensity oil lamps were provided. They were not intended to allow the driver to see the way ahead (locomotive drivers were expected to have sufficient route knowledge such that they knew where they were) but were used to indicate the class of a train by their position on the front of the locomotive. Four lamp irons were provided: one below the chimney and three evenly spaced across the top of the buffer beam.

In some countries heritage steam operation continues on the national network. Some railway authorities have mandated that it is necessary to have powerful headlights on at all times, including during daylight. This was to further inform the public of any active trains.

Bells and whistles

Locomotives were given bells and steam whistles from very early on. In the United States and Canada bells were used to warn that the train is in motion. In Britain, where all lines are by law fenced throughout,[10] they were never a requirement; whistles are used to signal personnel and give warnings.

Automatic Train Control

From early in the twentieth century operating companies in such countries as Germany and Britain began to fit locomotives with in-cab signalling which automatically applied the brakes when a signal was passed at "caution". In Britain these became mandatory in 1956.

Booster engines

In the United States and (sometimes) Australia the trailing truck was often equipped with an auxiliary steam engine which provided extra power for starting. This booster engine was set to cut out automatically at a certain speed.

Variations

Numerous variations to this basic arrangement appeared over the years. Some locomotives added extra cylinders and sometimes essentially combined two locomotives in one (e.g. the Mallet and Garratt locomotives). Some locomotives drove the wheels through a system of shafts and gears (e.g. the Shay locomotive; see "geared steam locomotive"). In the United States on the Southern Pacific Railroad a series of cab forward locomotives were built in which the entire machine was turned around, putting the cab and the firebox at the front of the locomotive. At the end of steam practice some attempts were made to employ steam turbines instead of reciprocating engines, both through direct drive and through electrical transmissions. These were not notably successful.[5]

Considerable improvements were made to the steam engine arrangement over the years. Early locomotives had very simple valve gear that allowed no more than full power applied in either forward or reverse.[6] Soon Stephenson valve gear was applied to allow the driver to control cutoff; this was largely superseded by Walschaert valve gear and similar patterns. Early practice used slide valves and outside admission, which were easy to construct but inefficient and prone to wear.[6] Eventually slide valves were superseded by inside admission piston valves, though there were attempts to apply poppet valves (common by then on stationary engines) in the 20th century. Stephenson valve gear was generally placed within the frame, where it was difficult to access for maintenance; later patterns were applied outside the frame, where they were readily visible and maintained.

Around 1900 compound engines were introduced. Some attempts were made to apply this to a single engine (e.g. the Vauclain compound) but the predominant form was the Mallet locomotive, which used two separate engines in one articulated frame. The high pressure stage was attached directly to the boiler frame; in front of this was a separate low pressure engine on its own frame, powered by the exhaust from the rear engine. Articulation itself proved very popular, and there were numerous variations, both compound and simple. Duplex locomotives with two engines in one rigid frame were also tried, but were not notably successful[citation needed].

Mixed power locomotive prototypes have been produced. The LNER had a prototype Kitson-Still hybrid built for testing, using a steam and diesel engine on a 2-6-2 wheelbase. It proved more efficient, but its running costs were 25% higher than an equivalent steam locomotive. Other prototypes were introduced; the LMS tried parallel high-low pressure boilered locomotive, called Fury. The LMS also built the Turbomotive, an attempt to prove the efficiency of steam turbines.[5]

Manufacture

With the notable exception of the USRA standard locomotives in the United States, steam locomotive manufacture was always somewhat customised. Railroads ordered locomotives tailored to their specific requirements, though basic similarities were always present. Certain railroads were noted for certain characteristics; for example, the Pennsylvania Railroad was known for its preference for the Belpaire firebox[citation needed], and the Delaware and Hudson Railroad was famous for its elaborately flanged smokestacks[citation needed]. In the United States locomotives were ordinarily built by specialised manufacturers, but all railroads had shops which were capable of massive repairs, and some railroads (for instance the Norfolk and Western Railway) built many locomotives in their own shops, as did the GWR at Swindon and the LNWR (latterly the LMS) at Crewe in the UK. It was not uncommon for a group of locomotives to be sold from one railroad to another[citation needed].

Steam locomotives required regular maintenance and overhaul (often at government-regulated intervals), and locomotives were frequently altered in the course of these. New appliances could be added, unsatisfactory features removed, and even new boilers, cylinders, and in fact almost any part of the locomotive replaced. In one case on the Baltimore and Ohio Railroad two 2-10-2 locomotives were taken apart; the boilers were used to make 4-8-2 locomotives with new machinery, and the machinery was used to make a pair of 0-10-0 switchers with new boilers[citation needed].

Categorisation

Steam locomotives are categorised by their wheel arrangement. The two dominant systems for this are the Whyte notation and UIC classification.

The Whyte notation, used in the most English speaking and Commonwealth countries, represents each set of wheels with a number. Different arrangements were given names which usually reflect the first usage of the arrangement; for instance the "Santa Fe" type (2-10-2) is so called because the first examples were built for the Atchison, Topeka and Santa Fe Railroad. These names were informally given and varied according to region and even politics.

The UIC classification is used mostly in European countries apart from the United Kingdom. It designates consecutive pairs of wheels (informally "axles") with a number for non-driving wheels and a capital letter for driving wheels (A=1, B=2 etc). So a Whyte 4-6-2 designation would be an equivalent to a 2-C-1 UIC designation.

On many railroads, locomotives were organised into classes. These broadly represented locomotives which could be substituted for each other in service, but most commonly a class represented a single design. As a rule classes were assigned some sort of code, generally based on the wheel arrangement. Classes also commonly acquired nicknames representing notable (and sometimes uncomplimentary[citation needed]) features of the locomotives.

Performance

In the steam locomotive era two measures of locomotive performance were generally applied. At first, locomotives were rated by tractive effort This can be roughly calculated by multiplying the total piston area by 85% of the boiler pressure (a rule of thumb reflecting the slightly lower pressure in the steam chest above the cylinder) and dividing by the ratio of the driver diameter over the piston stroke.[7] However, the precise formula is:

Tractive Effort is defined as the average force developed during one revolution of the driving wheels at the rail head. (Swengel, p.66.) This is expressed as;

T.E. = (B² x S x 0.85P) ÷ D

B is bore of cylinder (diameter)in inches. S is cylinder stroke, in inches. P is boiler pressure in pound per square inch; and D is driving wheel diameter in inches

It is critical to appreciate the use of the term 'average', as not all effort is constant during the one revolution of the drivers for at some points of the cycle only one piston is exerting turning moment and at other points both pistons are working. Not all boilers deliver full power at starting and also the tractive effort decreases as the rotating speed increases. (Swengel, p.66.)

Tractive effort is a measure of the heaviest load a locomotive can start or haul at very low speed over the ruling grade in a given territory.(Swengel)

However, as the pressure grew to run faster freight and heavier passenger trains, tractive effort was seen to be an inadequate measure of performance because it did not take into account speed.

Therefore in the 20th century, locomotives began to be rated by power output. A variety of calculations and formulas were applied, but in general railroads used dynamometer cars to measure tractive force at speed in actual road testing. This measure was termed drawbar horsepower in the United States and remained the standard measure of performance to the end of mainline usage[citation needed].

Whyte classification is connected to locomotive performance, but through a somewhat circuitous path. Given adequate proportions of the rest of the locomotive, power output is determined by the size of the fire, and for a bituminous coal-fuelled locomotive, this is determined by the grate area. Modern non-compound locomotives are typically able to produce about 40 drawbar horsepower per square foot of grate. Tractive force, as noted earlier, is largely determined by the boiler pressure, the cylinder proportions, and the size of the drivers. However, it is also limited by the weight on the drivers (termed adhesive weight), which needs to be at least four times the tractive effort.[5]

The weight of the locomotive is roughly proportional to the power output; the number of axles required is determined by this weight divided by the axleload limit for the trackage where the locomotive is to be used. The number of drivers is derived from the adhesive weight in the same manner, leaving the remaining axles to be accounted for by the leading and trailing bogies.[5] Passenger locomotives conventionally had two-axle leading bogies for better guidance at speed; on the other hand, the vast increase of the grate and firebox in the 20th century meant that trailing bogie was called upon to provide its support.

As a rule, "shunting engines" (US "switching engines") omitted leading and trailing bogies, both to maximise tractive effort available and to reduce wheelbase. Speed was unimportant; making the smallest engine (and therefore smallest fuel consumption) for the tractive effort paramount. Drivers were small and usually supported the firebox as well as the main section of the boiler. Helper engines tended to follow the principles of switchers, except that the wheelbase limitation did not apply. Therefore helpers tended to multiply the number of drivers, leading eventually to the Mallet type with its many driven wheels. These tended to acquire leading and then trailing bogies as guidance of the engine became more of an issue.

As locomotive types began to diverge in the late 1800s, freight engines at first emphasised tractive effort, whereas passenger engines emphasised speed. Freight locomotives multiplied axles, kept the leading bogie to a single axle, and grew a trailing bogie as the firebox expanded and could no longer fit between or above the drivers. Passenger locomotives had two axle leading bogies, fewer axles, and very large drivers in order to limit the speed at which the reciprocating parts had to move.

In the 1920s the focus in the United States turned to horsepower, epitomised by the "super power" concept promoted by the Lima Locomotive Works. Freight trains were to be driven faster; passenger trains needed to pull heavier loads at speed. In essence, the grate and firebox expanded without changes to the remainder of the locomotive, forcing the trailing bogie to grow a second axle. Freight 2-8-2s became 2-8-4s while 2-10-2s became 2-10-4s. Similarly, passenger 4-6-2s became 4-6-4s. In the United States this led to a convergence on the dual-purpose 4-8-4 configuration, which was used for both freight and passenger service.[11] Mallet locomotives went through a similar transformation and were upgraded from helpers into huge road engines with gargantuan fireboxes; their drivers increased in size in order to allow faster running.

In Australia, Clyde Engineering of Sydney and also the Eveleigh Workshops built steam locomotives for the New South Wales Government Railways. These include the C38 class 4-6-2, the first five were build at Clyde with streamlining, the other 25 locomotives were built at Eveleigh (13) in Sydney, and Cardiff Workshops (12) near Newcastle. In Queensland, steam locomotives were locally constructed by Walkers. Similarly the South Australian state government railways also manufactured steam locomotives locally at Islington in Adelaide. The Victorian Railways constructed most of their locomotives at their [[Newport Workshops and Bendigo while in the early days locomotives were built in Ballarat. Locomotives constructed at the Newport shops ranged from the nA class 2-6-2T built for the narrow gauge, up to the H class 4-8-4, the largest conventional locomotive ever to operate in Australia, which weighed 260 tons. However, the title of largest locomotive in Australia goes to the 263 ton NSWGR AD60 class 4-8-4+4-8-4 Garratt(Oberg, Locomotives of Australia), which were built by Beyer-Peacock in the United Kingdom.

The end of steam

The introduction of diesel-electric locomotives in the first part of the 20th century spelled the end of steam locomotives[citation needed], though they were used in the North American and Europe to mid-century, and continued in use in other countries to the end of the century. Steam locomotives can be fairly simple machines, maintainable under fairly primitive conditions and amenable to a wide variety of fuels. They are also relatively inefficient and require constant maintenance, and need substantial labour to do so.[12] Water must be supplied at many points throughout the system, a problem in desert areas or where the local water is unsuitable. The reciprocating mechanism pounds on the rails (see "hammer blow"), thus requiring more maintenance of way. Steam locomotives require several hours' boiling up before service and an end-of day procedure to remove ash and clinker, unlike a diesel or electric locomotive which starts working from the first turn of the key and can be put away at night just as quickly.[13] Finally, the smoke from steam locomotives is frequently objectionable; in fact, the first electric and diesel locomotives were developed to meet smoke abatement requirements.[13]

Mainline diesel-electric locomotives were first introduced on the Baltimore and Ohio Railroad, and were soon found to reduce operating and maintenance costs dramatically, while increasing locomotive availability. On the Chicago, Rock Island and Pacific Railroad the new units were found to deliver over 350,000 miles a year, compared with about 120,000–150,000 for a mainline steam locomotive.[5] World War II delayed dieselisation, but the pace picked up in the 1950s, and by 1960 the last American Class I holdout, the Norfolk and Western Railway, had discontinued steam operations. Some shortlines continued steam operations into the 1960s, and one steel mill continued to operate steam locomotives up to 1980 [citation needed]. In the United Kingdom the availability of cheap domestic-produced coal kept steam in widespread use until the 1960s, when rising labour costs led to its phasing out in 1968[citation needed]. At the end of steam British Railways estimated that its steam locomotives were costing around four times more in running costs than diesels (even though most of its steam locomotives were allowed to deteriorate to a sorry state of repair before being scrapped)[citation needed]. The use of steam locomotives in British industry continued until 1974[citation needed].

In some other countries steam remained in wide use and continued to the end of the twentieth century. Diesel locomotives were relatively expensive and the pressure of labour costs was not as great. The expense of oil gave other fuels a cost advantage.

In South Africa an oil embargo combined with an abundance of cheap local coal prompted the use of steam locomotives into the 1990s[citation needed]. Locomotive engineer, L. D. Porta's designs appeared on a Class 19D engine in 1979, then a former Class 25, became class 26, termed the "Red Devil" No. 3450, which demonstrated an improved overall performance with decreased coal and water consumption. The single class 26 locomotive operated until the end of steam. Another class 25NC locomotive, No. 3454, nicknamed the "Blue Devil" because of its colour scheme received modifications including a most obvious set of double side-by-side exhaust stacks. In southern Natal, two former South African Railway 2 ft (610 mm) gauge NGG16 Garratts operating on the privatised Port Shepstone & Alfred County Railway (ACR)received some L. D. Porta modifications in 1990 becoming a new NGG16A class.(See video citations)

China continued to build mainline steam locomotives until late in the century, even building a few examples for American tourist operations[citation needed].

Dramatic increases in the cost of diesel fuel prompted several initiatives to revive steam power[14][15]. None of these has progressed to the point of production, and in the early 21st century the steam locomotives operate only in a few isolated regions and in tourist operations.

References

- ↑ 1.0 1.1 Payton, Philip (2004): Oxford Dictionary of National Biography. Oxford University Press.

- ↑ Hamilton Ellis (1968). The Pictorial Encyclopedia of Railways. The Hamlyn Publishing Group, pp.24-30.

- ↑ Hamilton Ellis (1968). The Pictorial Encyclopedia of Railways. The Hamlyn Publishing Group, p.32.

- ↑ National Museum of American History article on locomotive crews.

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 Bell, A Morton (1950): Locomotives, seventh edition. Virtue & Co Ltd, London.

- ↑ 6.0 6.1 6.2 Snell, John B (1971): Mechanical Engineering: Railways. Longman, London.

- ↑ 7.0 7.1 Adams, Henry (1907): Cassell’s Engineers’ Handbook. Cassell and Co, London.

- ↑ U.S. National Parks Service online history resource: Pennsylvania Railroad chemical laboratory. Accessed 9 November 2006.

- ↑ Unknown author (1957): Handbook for Railway Steam Locomotive Enginemen. British Transport Commission.

- ↑ Section 10, Railway Regulation Act, 1842. Her Majesty's Stationery Office.

- ↑ Allen, Cecil J (1949): Locomotive Practice and Performance in the Twentieth Century. W Heffer and Sons Ltd, Cambridge, England.

- ↑ 1935 article on the advantages of diesel locomotives.

- ↑ 13.0 13.1 Diesel Traction Manual for Enginemen, 15-16. British Transport Commission, 1962.

- ↑ The 5AT project to develop a modern steam locomotive for British railways.

- ↑ Railway Extension Across the Andes: reactivation and modernisation of existing fleet of 75cm gauge 2-10-2 steam locomotives.

- Swengel, F.M. The American Steam Locomotive, Vol.1, The Evolution of the Steam Locomotive, MidWest Rail Publications, Davenport, 1967.

South African end of Steam video VidRail Productions, "Orange Free State, Part 4, Vols. 3, 4 and 5" and "Natal, Part 3, Vol. 1", in The Best of Southern African Steam, 1983-1990

See also

External links

| Wikimedia Commons has media related to: Steam locomotives |

- Database of surviving steam locomotives in North America

- Information on North American steam railroads in operation

- UK heritage railways and preserved locomotives database

Books on steam locomotives

- C. E. Wolff, Modern Locomotive Practice: A Treatise on the Design, Construction, and Working of Steam Locomotives (Manchester, England, 1903)

- Henry Greenly, Model Locomotive (New York, 1905)

- G. R. Henderson, Cost of Locomotive Operation (New York, 1906)

- W. E. Dalby, Economical Working of Locomotives (London, 1906)

- A. I. Taylor, Modern British Locomotives (New York, 1907)

- E. L. Ahrons, The Development of British Locomotive Design (London, 1914)

- E. L. Ahrons, Steam Engine Construction and Maintenance (London, 1921)

- J. F. Gairns, Locomotive Compounding and Superheating (Philadelphia, 1907)

- Angus Sinclair, Development of the Locomotive Engine (New York, 1907)

- Vaughn Pendred, The Railway Locomotive, What it is and Why it is What it is (London, 1908)

- Brosius and Koch, Die Schule des Lokomotivführers (thirteenth edition, three volumes, Wiesbaden, 1909-1914)

- G. L. Fowler, Locomotive Breakdowns, Emergencies, and their Remedies (seventh edition, New York, 1911)

- Fisher and Williams, Pocket Edition of Locomotive Engineering (Chicago, 1911)

- T. A. Annis, Modern Locomotives (Adrian Michigan, 1912)

- C. E. Allen, Modern Locomotive (Cambridge, England, 1912)

- W. G. Knight, Practical Questions on Locomotive Operating (Boston, 1913)

- G. R. Henderson, Recent Development of the Locomotive (Philadelphia, 1913)

- Wright and Swift (editors) Locomotive Dictionary (third edition, Philadelphia, 1913)

- Roberts and Smith, Practical Locomotive Operating (Philadelphia, 1913)

- E. Prothero, Railways of the World (New York, 1914)

- M. M. Kirkman, The Locomotive (Chicago, 1914)

- C. L. Dickerson, The Locomotive and Things You Should Know About it (Clinton, Illinois, 1914)

- P. W. B. Semmens, A. J. Goldfinch, How Steam Locomotives Really Work (Oxford University Press, USA, 2004) ISBN 0-19-860782-2

- Gerald A Dee, "A Lifetime of Railway Photography' in Photographer Profile, Train Hobby Publications, Studfield, 1998. (steam downunder)

- Leon Oberg, Locomotives of Australia, Reed, Sydney, 1975.