Walschaert valve gear

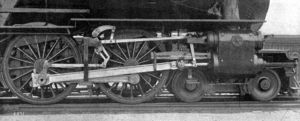

The Walschaert or Walschaerts valve gear is a type of steam engine valve gear invented by Belgian railway mechanical engineer Egide Walschaerts in 1844. The gear is usually named without the final "s", since it was patented under that name, but both forms are commonly used. It was extensively used in steam locomotives from the late 19th century until the end of the steam era.

Contents

History

It was slow to gain popularity. The Stephenson valve gear remained the most popularly used valve gear on 19th-century locomotives. The Walschaert gear had the advantage that it could be mounted entirely on the outside of the locomotives, leaving the space between the wheels and frames clear; this caused adoption first among some articulated locomotives. The Mason Bogie locomotive type was the first to use the Walschaert gear in North America.

In the 20th century, the Walschaert valve gear was the most commonly used gear, especially on larger locomotives. In Europe, its use was almost universal, while in North America, the Walschaerts gear outnumbered its closest competitor, the Baker valve gear, by a wide margin.

In Germany, the Walschaert gear is often named the Heusinger valve gear after Edmund Heusinger von Waldegg, who invented the mechanism independently in 1849. Heusinger's gear was closer to the form generally adopted, but most authorities accept Walschaerts' invention as sufficiently close to the final form.

Technical details

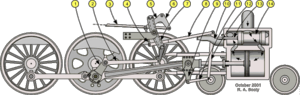

The Walschaert valve gear, when correctly designed, provides constant valve lead irrespective of the chosen cutoff in both forward and reverse gear. With the piston in the front or rear dead centre positions, the expansion link should be vertical and moving the die block up and down should not alter the valve spindle position.

The amount of lead provided is determined by the proportions of the combination lever and the lap designed into the valve. It can only be changed by changing the proportions of these components.

The valve gear operation combines two motions; one is the lead motion and the other is the directional motion required in full gear. To understand the operation, consider the cutoff in mid-gear. Because the die block does not move, the end of the radius rod is in effect a fixed point about which the combination lever pivots, so the valve motion is that caused directly by the cross head motion acting through the union link and combination lever. This moves the valve in each direction by a distance which should be set equal to lap plus lead of the valve.

If this were the only motion made by the valve then the engine would only start if the piston were close to dead centre, and even then the direction in which the engined moved would depend upon whether it was fractionally before or after the dead centre point.

Outside admission valves

Consider the case of outside admission valves such as slide valves. A second motion is superimposed on the crosshead motion to the valve; the return crank provides a motion which lags the crankpin motion by 90 degrees. By choice of position of the reach rod the die block may be moved from top to bottom which superimposes a varying portion of this motion ranging from either 90 degrees in lag behind the crank (full forward gear) through none in midgear to 90 degrees leading the crank (full reverse gear). Lag and lead of these motions are always described relative to the engine moving forwards. The larger the magnitude of the superimposed component, the later the cutoff and thus the less expansion allowed for the steam in the cylinder.

Internal admission valves

For internal admission valves (most piston valves, but there are some exceptions on rebuilt locomotives) the lag and lead motions must be reversed usually by placing the return crank 90 degrees in advance of the crank pin and the combination rod pivots on the radius rod above the linkage to the valve rods instead of below. This is the case shown in the diagrams above.

Layout

To layout the Walschaert gear the proportions of the combination lever must be chosen. The total movement of the valve rod in mid gear should be symmetric between front and back dead center. A displacement of the union link end by half the piston travel must cause a valve rod displacement of the valve lead plus the valve lap. The ratio of distance from union link end to pivot with radius rod to the distance between the valve rod end to the pivot with the radius rod should be in the same proportion as half piston travel to valve lap plus lead.

Next the fact that in midgear, the valve opening should be the same for the piston in both front and rear dead center positions is used to find the mid gear position of the pivot between the combination rod and reach rod. In practise the valve spindle length is adjusted to ensure this as part of setting the timing.

With the reverser in mid gear position since there should be no superimposed return crank motion, the expansion link die slot should be an arc of a circle centered on the pivot in mid gear and of radius equal to the length of the radius rod. This condition precludes adjustment of the valve gear by altering the length of the radius rod.

The throw of the return crank must now be determined; it should be such as in full forward and reverse gear to cause a total movement of the valve rod equal to two times (valve lap plus port opening). The actual throw required from the crank is determined from the dimensions of the expansion link.

References

Greenly, H., "Waelscharts Valve Gear", Marshall